Reservation Insights

9. Reservation Insights¶

9.1. Sales Order Line Subpage incl. Reservations¶

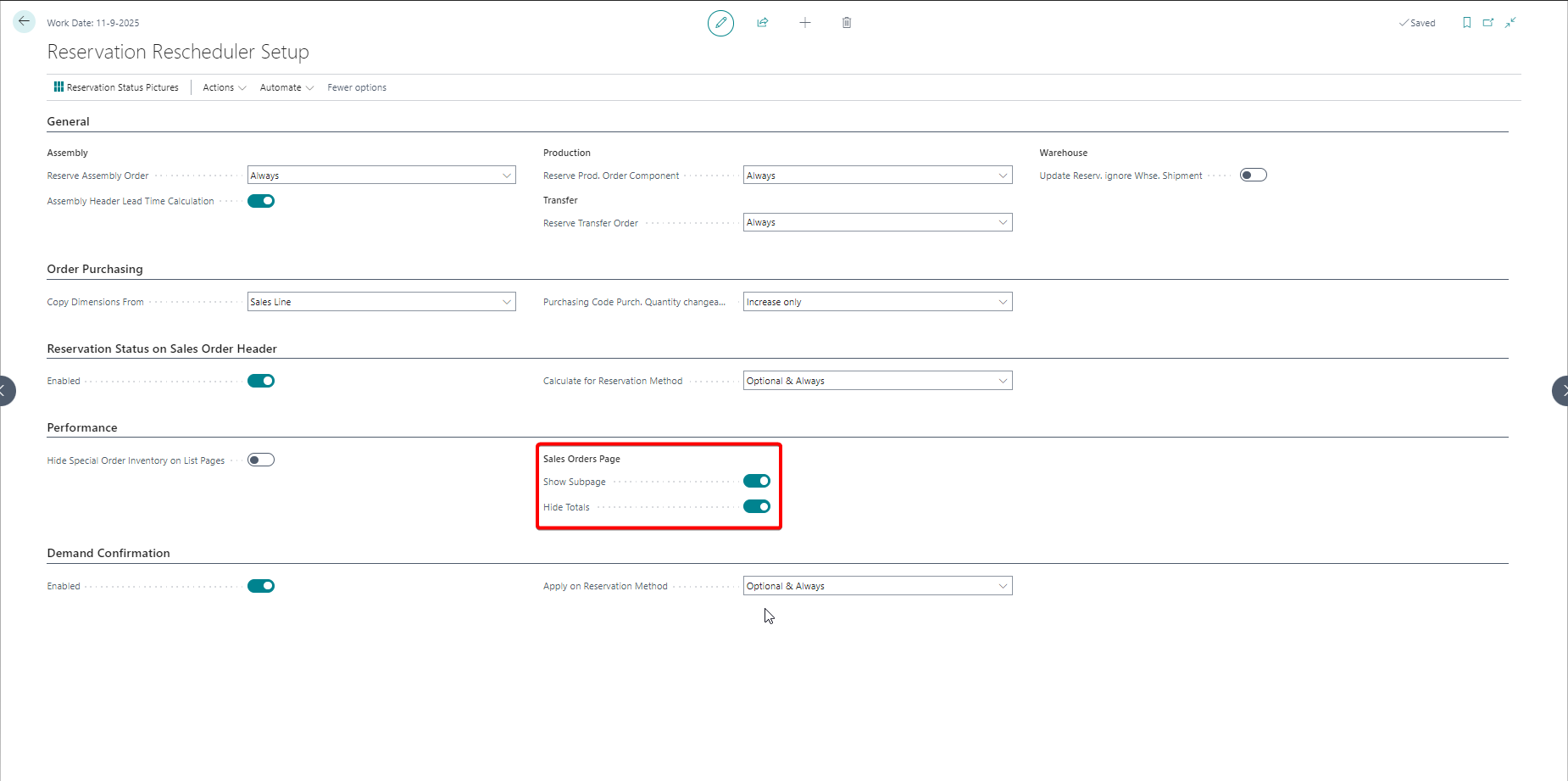

In the Reservation Rescheduler Setup page you can activate the possibility Show Sales Order Lines Subpage incl. Reservations. You can also hide the totals from the Sales Order on this subpage.

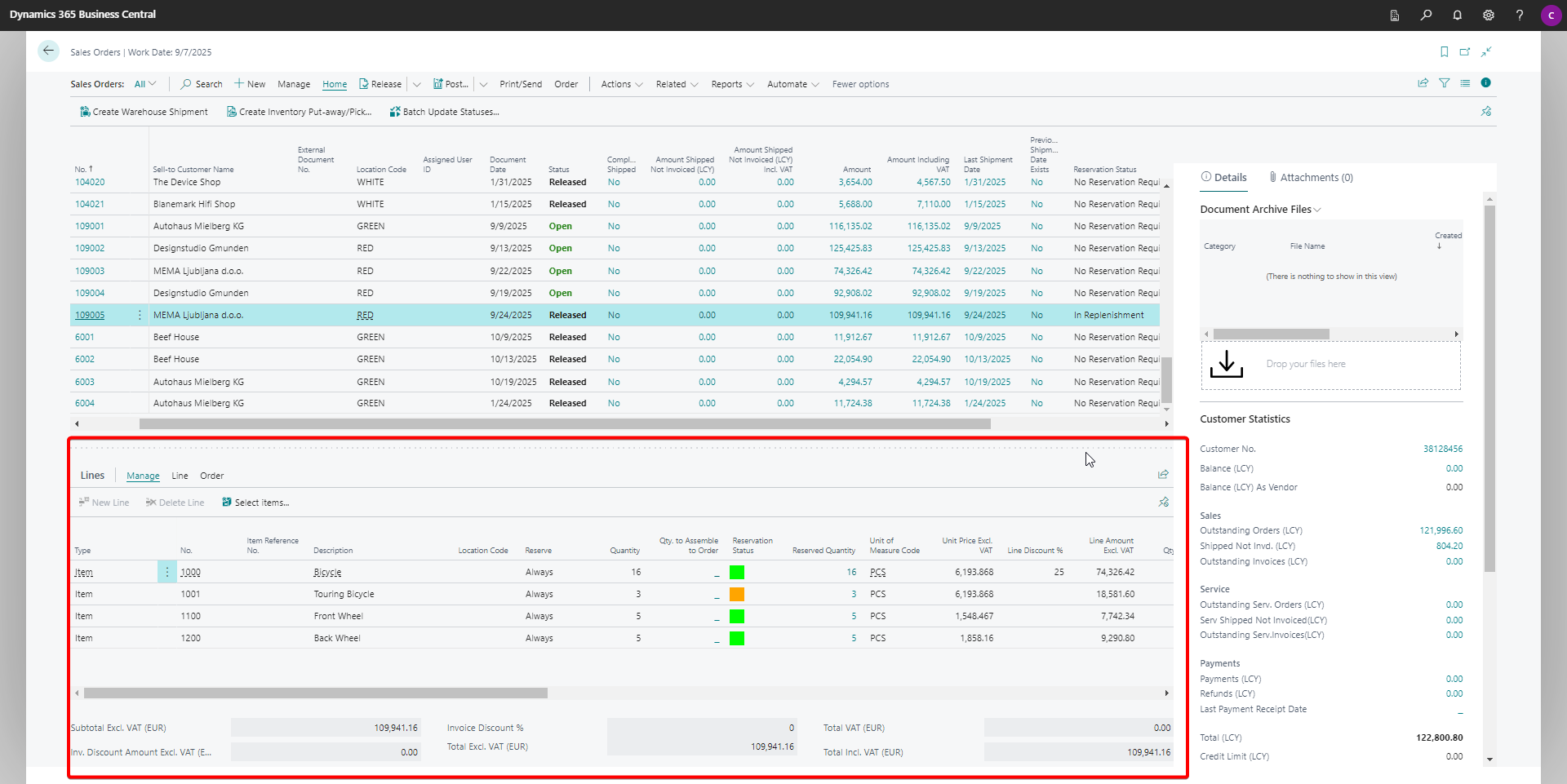

When activated this will give you in the Sales Order List a direct insight into the complete list of your Sales Orders and the related Sales Order Lines on a subpage. Of course, with the Reservation Status from the lines also insightful. Also, with all the available actions from the Sales Order and Sales Lines in one page.

You can activate or deactivate this view per user. The setting chosen in the Reservation Rescheduler Setup is the default setting. In the User Setup you have the options:

- Default Depending off the default setting this will be Active or Inactive

- Show Sales Order Subpage will be shown

- Hide Sales Order Subpage will not be shown

9.2 Reservation Status¶

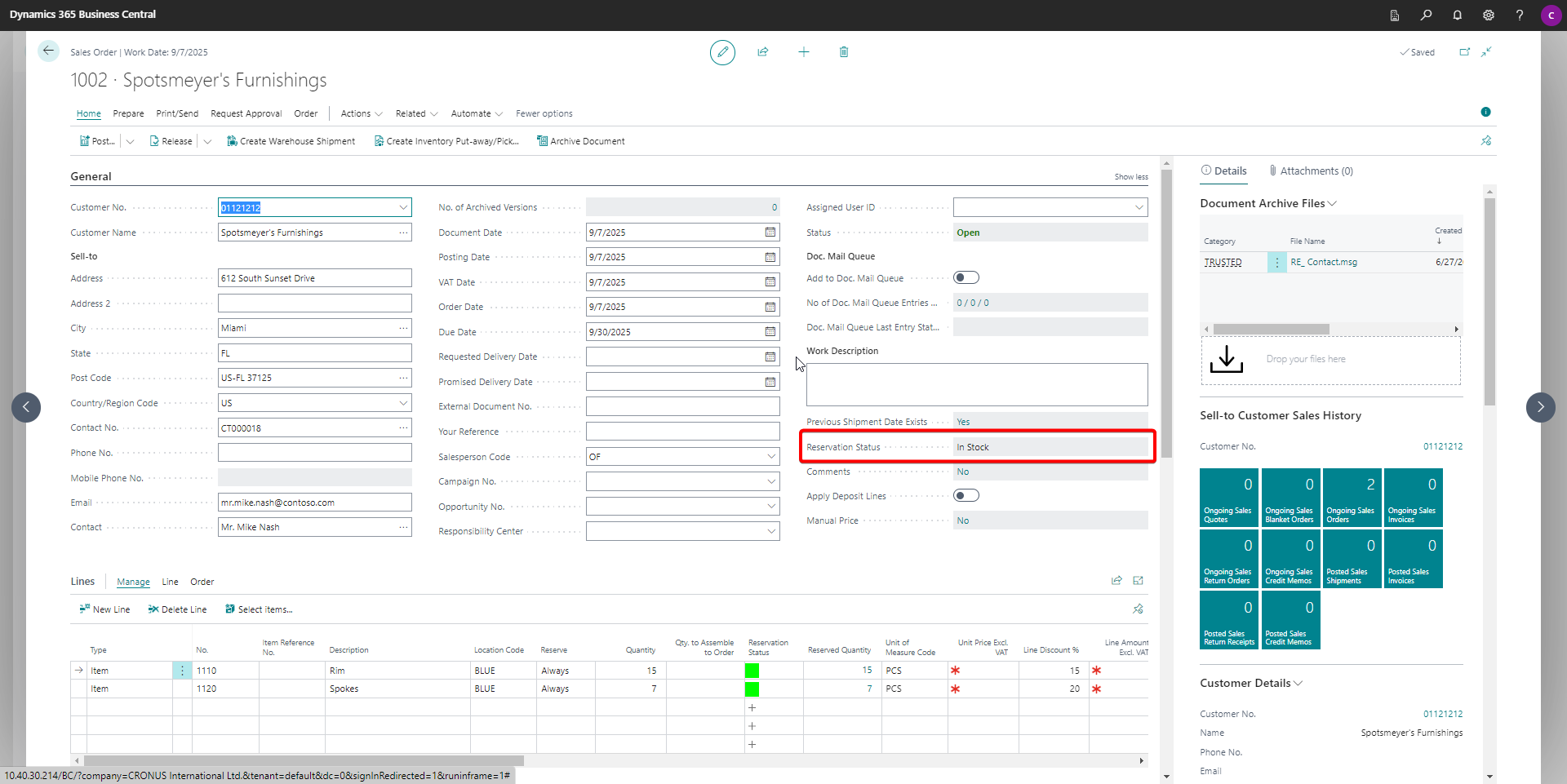

In the Sales Order we’ve added the Reservation Status. This field indicates the results from combined Reservation Status of the Sales Order lines. The status of the order is set by the most unfavorable reservation status in the lines.

| Priority | Reservation State (lines) | Reservation State (header) |

|---|---|---|

| 1 | One reservation not made (red) | To Replenish |

| 2 | One reservation from replenishment (orange) | In Replenishment |

| 3 | All reservations from stock (green) | In Stock |

Info

The Reservation Status on the order only calculates the lines where Reserve is set to Always

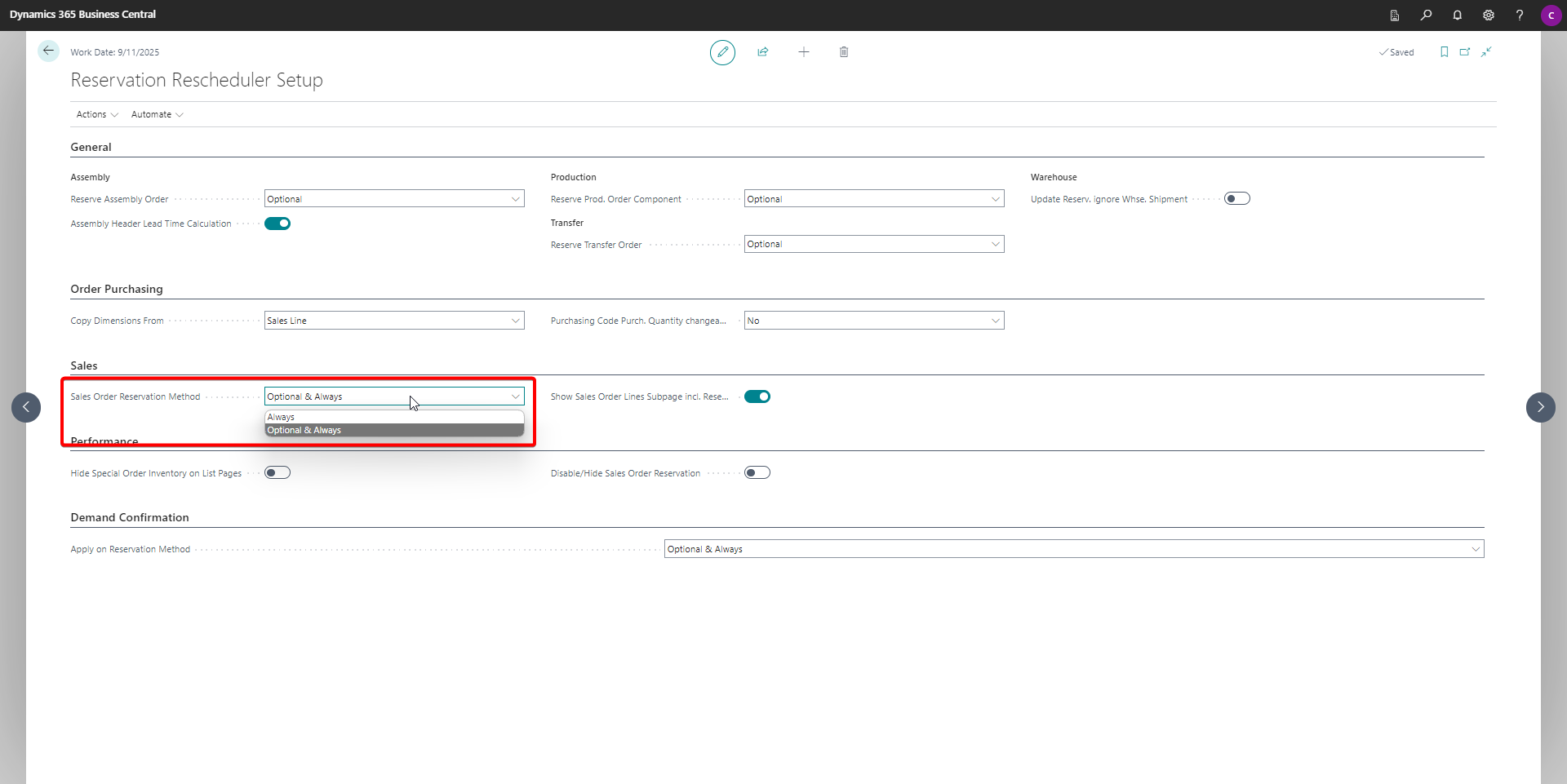

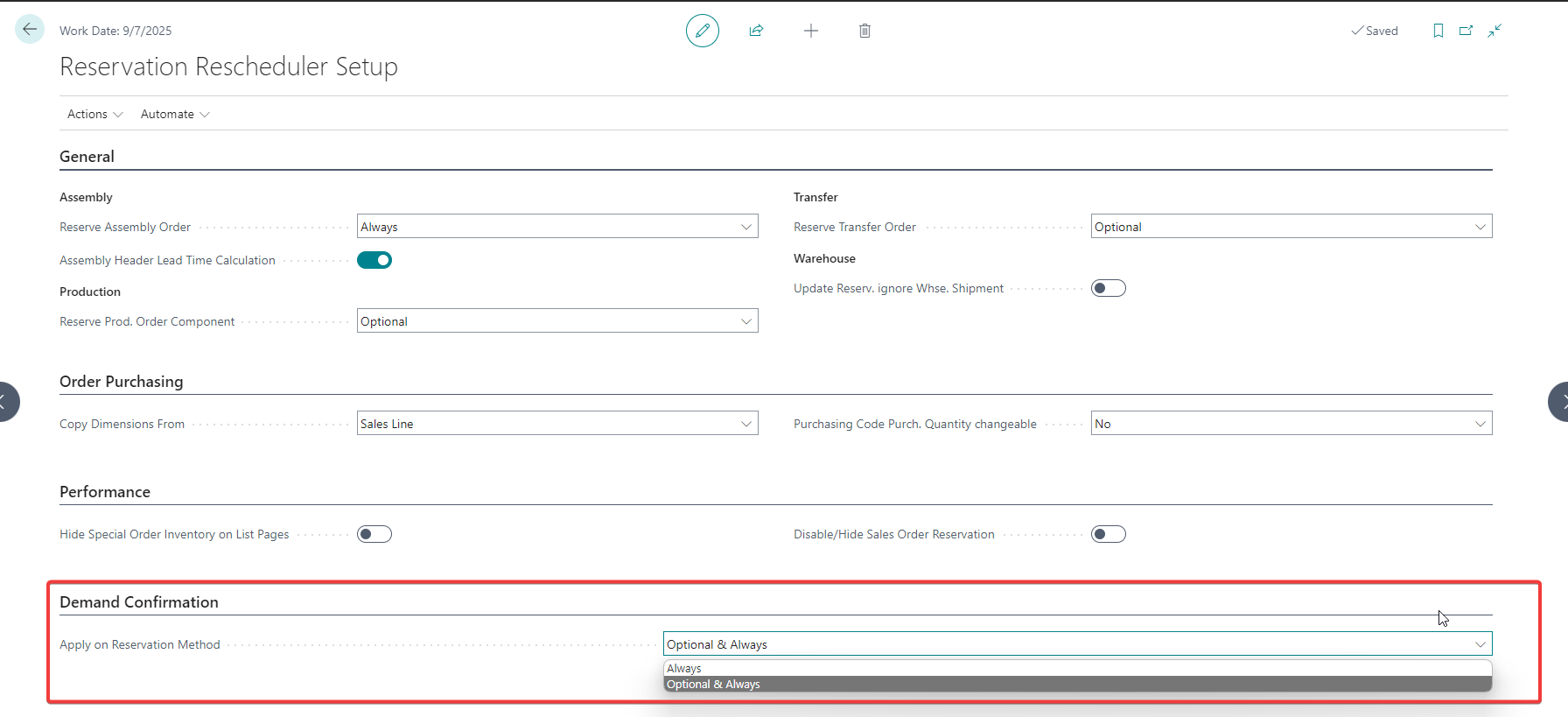

In the Reservation Rescheduler Setup you can choose which lines are to be included. Lines with Reserve setting Always or with Optional & Always, as shown in the screenshot below:

The Reservation State is available on the Sales Order page, Sales Order list & the Sales Order Reservation Overview.

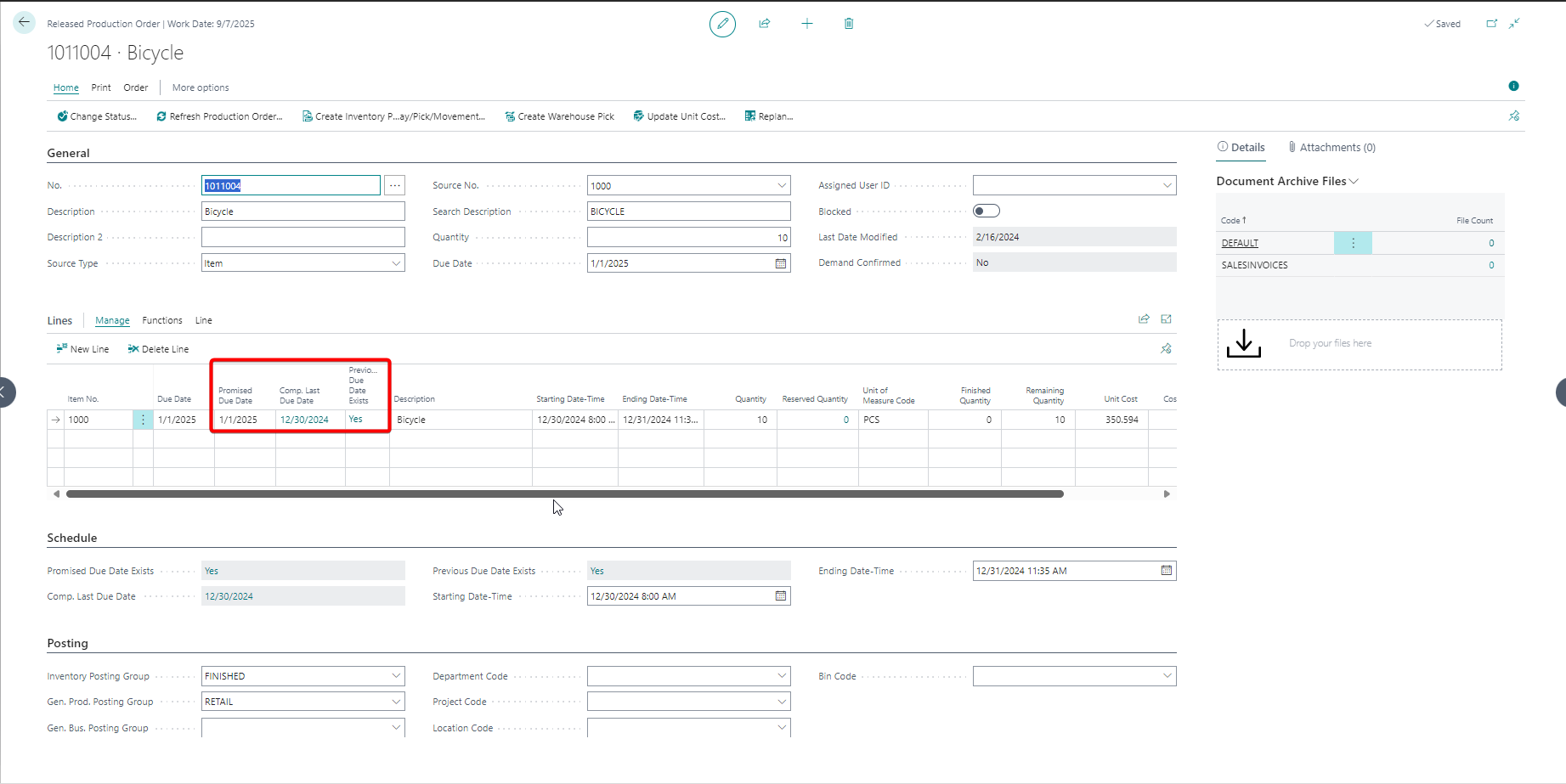

9.3 Previous Shipment/Due Date Indicator¶

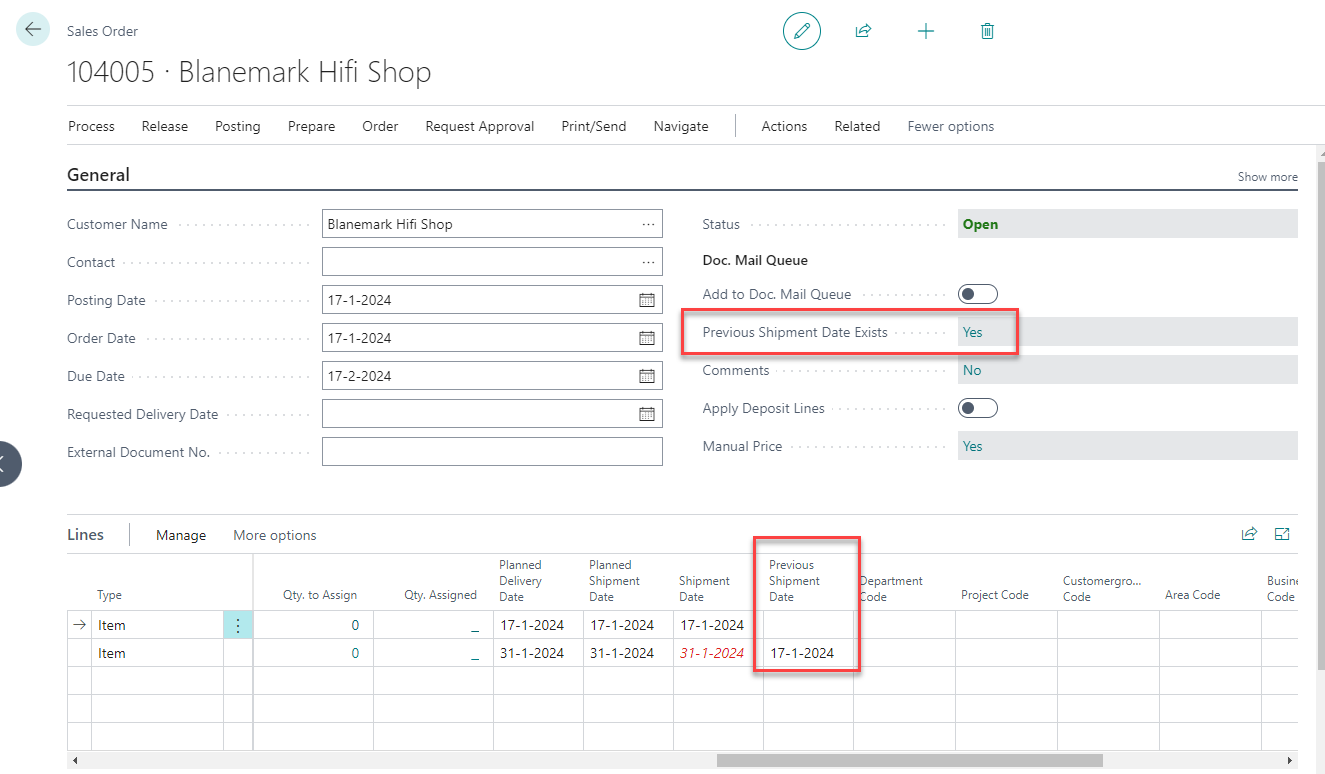

On the header of the documents that have the Reservation Rescheduler feature there is a True/False indicator present which will indicate whether there are lines present with a previous shipment/due date filled in. This will give you the opportunity to actively check the documents and document lines that have a changed shipment/due date. If one line in the document has an earlier date the Previous Shipment Date Exists field will show Yes, as shown in the sales order in the example seen in the screenshot below:

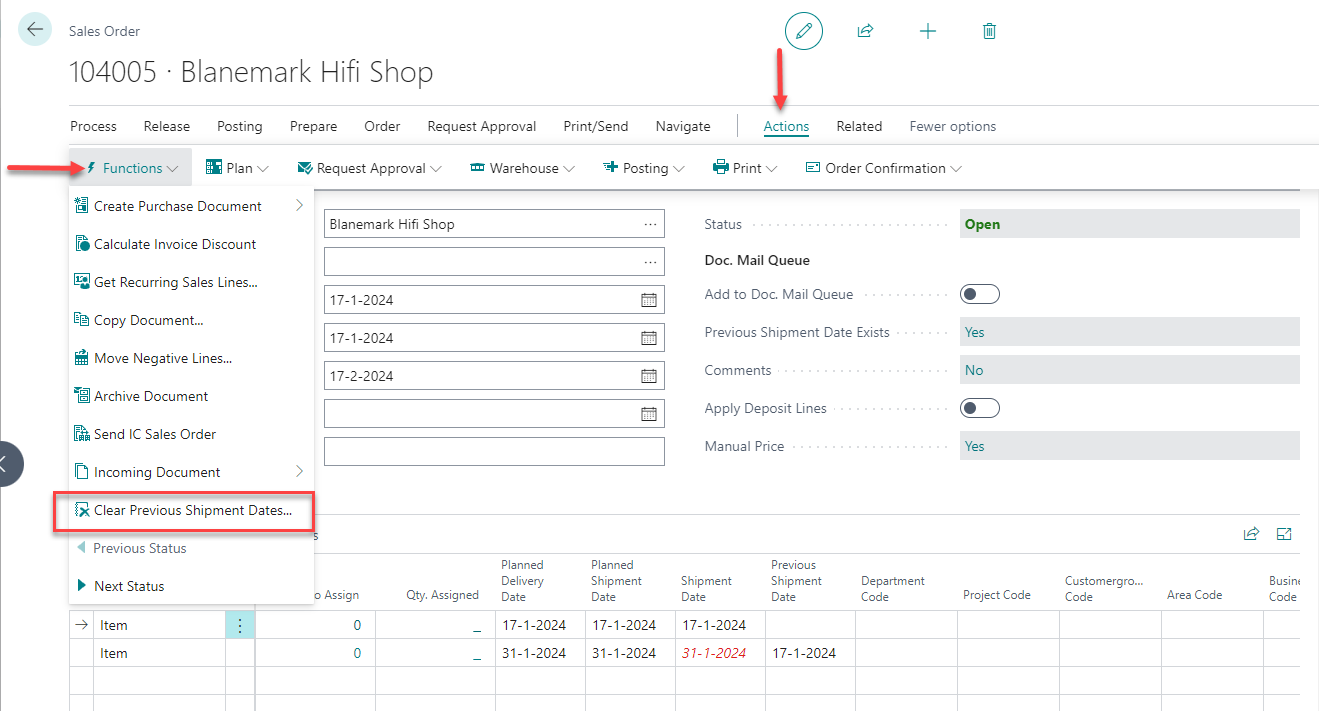

To clear this previous date in the lines an action is added to clear them. This action is added to the Functions group for the actions of the document:

By running the Clear Previous Shipment Dates action, a confirmation dialog will be shown. When you confirm clearing the previous dates, by selecting Yes, all the previous dates will be removed from the lines.

9.4 Demand Confirmed¶

On the header of the documents that have the Reservation Rescheduler feature there is a True/False indicator present. This indicator will only show Yes when all the lines present have their demand confirmed, as shown in the Sales Order in the example seen in the screenshot below:

- The Demand Confirmed field is calculated based on the Reservation Status.

- Not available, Reservation Status = Red --> Demand Confirmed = No

- Purchase Order is present, Reservation Status = Orange --> Demand Confirmed = No

- Purchase Order is present with a filled in Promised Receipt Date, Reservation Status = Orange --> Demand Confirmed = Yes

- On stock, Reservation Status = Green --> Demand Confirmed = Yes

In the Reservation Rescheduler Setup you can choose which lines are to be included. Lines with Reserve setting Always or with Optional & Always, as shown in the screenshot below:

Demand Confirmed is integrated in the following applications areas

- Sales

- Service

- Production

- Assembly

- Projects\

9.5 Advanced Due Date control¶

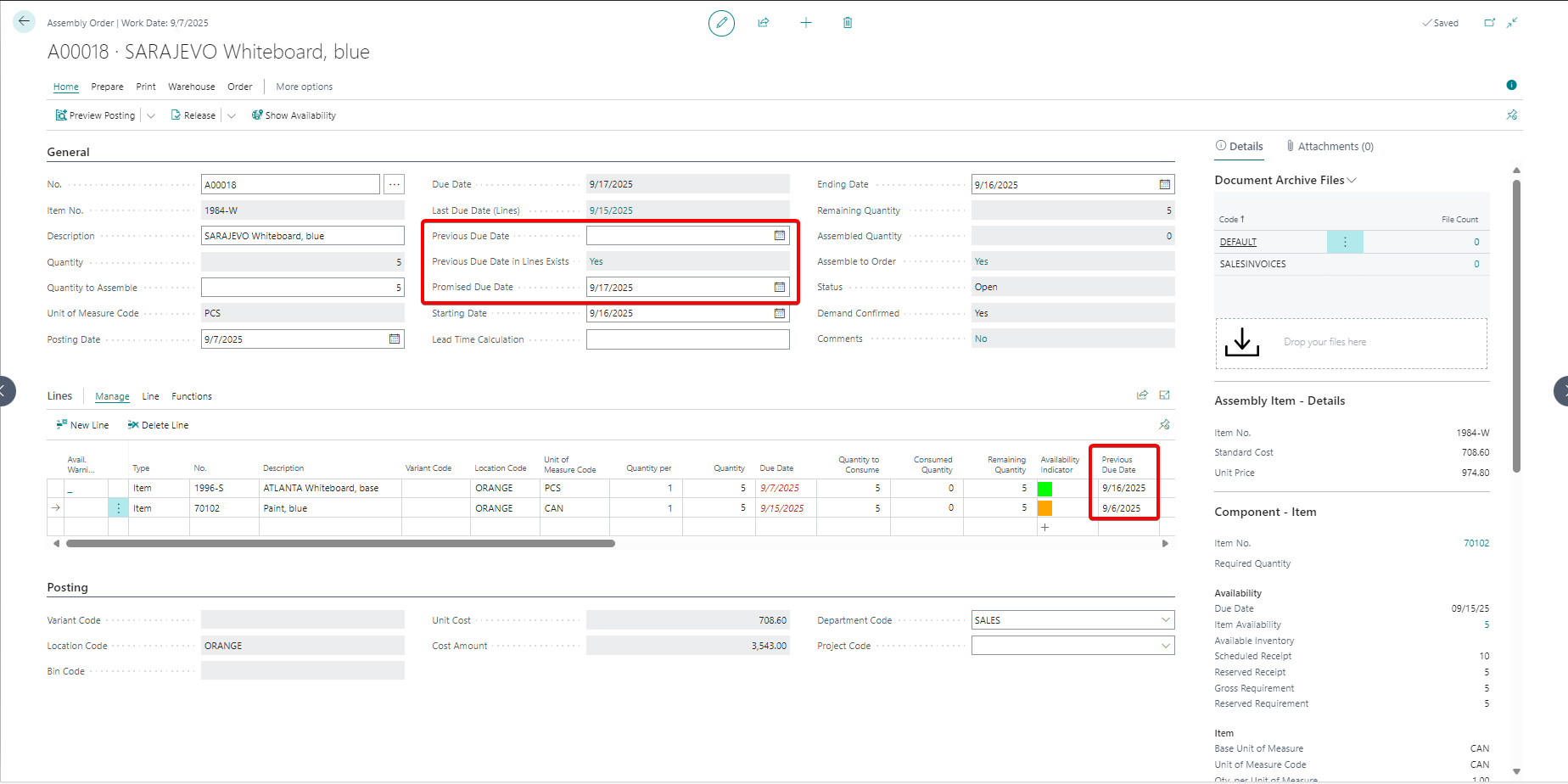

The Due Date in the Assembly & Production Order specifies the date when the assembly or production item should be available. To gain more control, including the use of reservations, the following fields have been added to the Reservation Rescheduler.

The fields are available in the Assembly Header & Production Order Line.

-

Previous Due Date Specifies the last Due Date before the new Due Dte was set by the Reservations Update batch

-

Previous Due Date in line exists Specifies if a Previous Due Date exists in the assembly / component lines

-

Component last Due Date Only available for Production: Specifies the latest Due Date found in the component lines

-

Promised Due Date Specifies the date that has been promised to as the due date for the assembly / production item

Previous Due Date¶

The previous due date fields are explained in the following scenarios

- Scenario 2.4: An Item with Assembly BOM on the Sales Order Line, shifting Purchase Order Receipt Date.

- Scenario 2.7: Stock available in PO for Item, Assembly Order Due Date move forward, run Reservation Update Report, Shipment Date Sales Order move forward

- Scenario 3.4: An Item with Production BOM on the Sales Order Line, shifting Purchase Order Receipt Date

Promised Due Date¶

The Promised Due Date for Assembly and Production is added to behave in the same way as the Promised Receipt Date of the Purchase Order for the feature Demand Confirmed. This means that e.g., a Sales Line with a production item is considered as Demand Confirmed when the Promised Due Date in the Production Order Line, from which the sales line is reserved, is populated

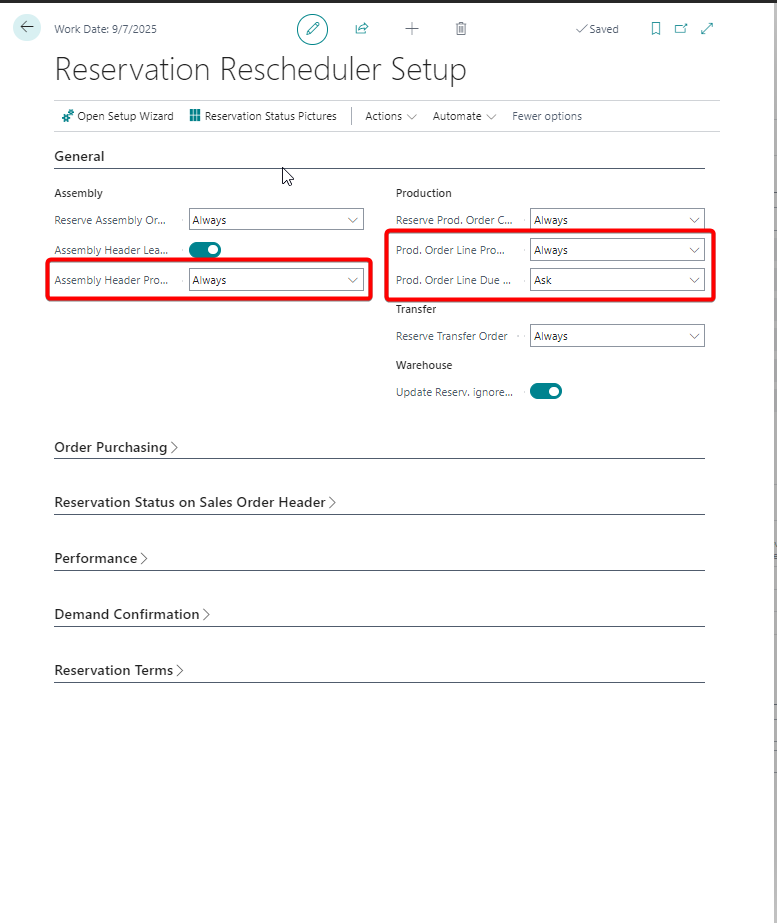

It is also possible to update the Due Date by changing the Promised Due Date. This behavior is controlled by the corresponding setting in the Reservation Rescheduler Setup.

Assembly Header / Prod. Order Line Promised Due Date update Due Date

- Never

- Always

- Ask

If you move the Due Date of the Production Order Line forward, standard behavior may automatically break and drop the outstanding reservations of the component. With the following setting in the Reservation Rescheduler Setup you can protect the reservations of the components

Prod. Order Line Due Date update allow Component reservation removal

- Never

- Always

- Ask

Note: updating the Due Date of the Prod. Order Line will also update the Starting Date-Time & Ending Date Date-Time of the Prod. Order Line and the Due Date of the Production Order, considering the Safety Lead Time as configured on the Item card or in the Manufacturing Setup.